I presented this box to my girlfriend in 2021.

Full build of the dovetailed tea box originally done By Mike Pekovich from Fine Woodworking issue No.269. I encourage you to check out the plans for this project or at least the issue that featured this project for detailed measurements.

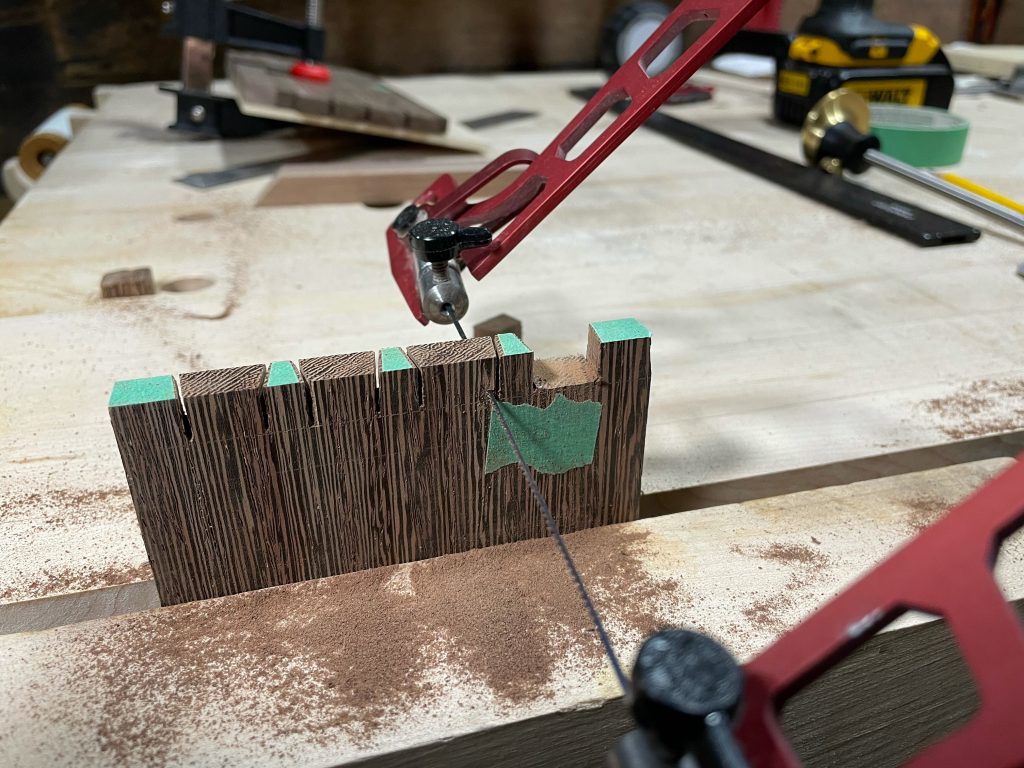

I used the same materials and dimensions from the article, wenge exterior, with curly/bird’s eye maple for the inner liner.

The wire brush was used on the wenge box parts to give enhanced texture by basically brushing away the soft grain lines.

The only clip I missed recording was gluing in the wedge dowel in the elongated slot in the base where the two cords passed through to secure them tightly (14:30).

Router bit used to clear out dovetail waste: Whiteside #3000 Template Bit with Ball Bearing (1/4″ Shank, 1/2″ Cutting Diameter, 1/4″ Cutting Length).