I turned my first bowl from a piece of well dried wood I picked up from an estate sale. Not sure what kind of wood it is, possibly cedar.

I think it turned out excellent for my first bowl.

I made another wall mounted tool holder to declutter my bench. This one holds my @leevalleytools Veritas bar gauge set and my beam compass with all their related extension rods and different tips. This took a while for me to think of a logical way to hold everything.

I’ve finished the first full sized dummy since the last pine mock up short version. Solid ash, the main trunk is 80lb without any arms or leg.

It has a wall mount and the bottom has a 4×4” hole to sit on a floor stand.

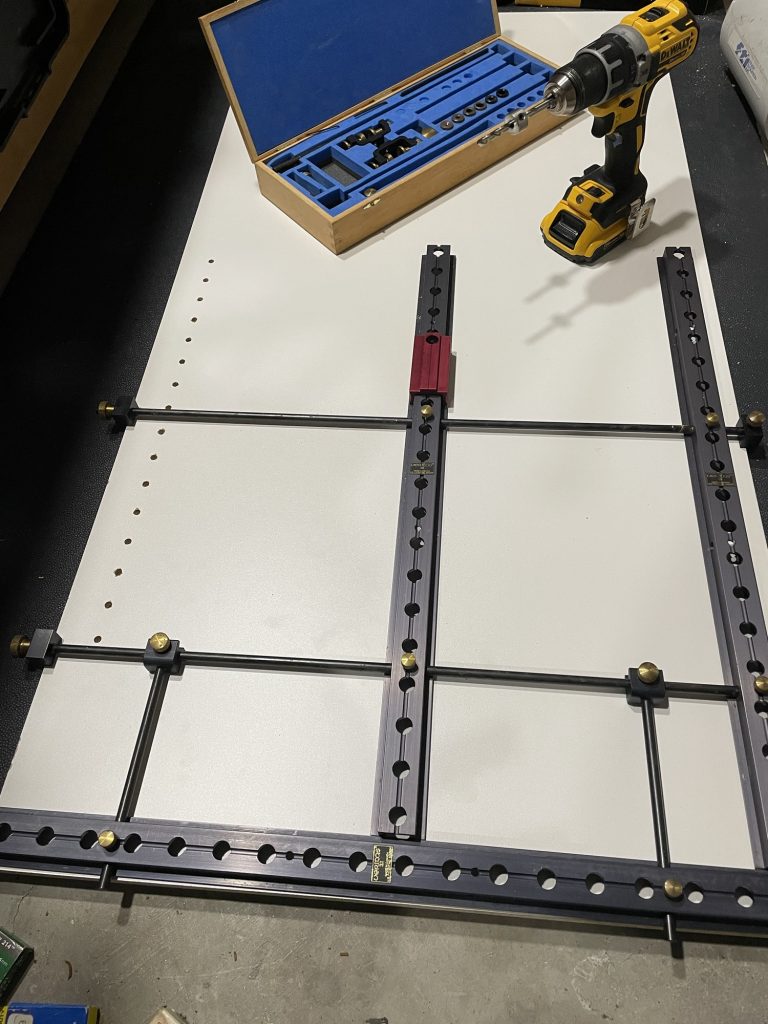

Well that was interesting. I’m playing with a @leevalleytools Veritas 32mm cabinet system jig to drill shelf holes in a shop cabinet I’m building. It works well but I find I’m getting chips in the melamine when drilling holes. Maybe I should have put blue tape where the holes are going to a brad point bit. I’m only using it to drill the shelf holes not the construction dowel holes for now.

I’ve had these @festoolcanada parallel guides for about 10 years and haven’t used them until today. Normally my tablesaw does all the parallel cut I need but these 8 foot long boards needed to be crosscut and the 24” width was too big for the mitre saw. They worked well. Too bad I couldn’t use my STM 1800 cutting cart, too many voids so I went out and bought foam to cut on the ground.

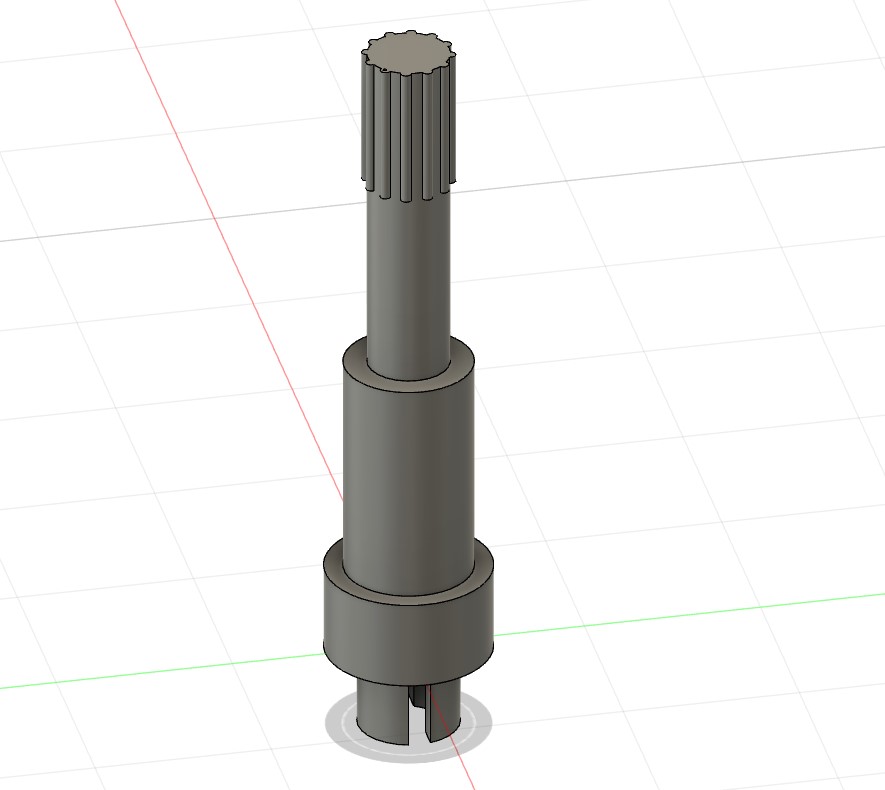

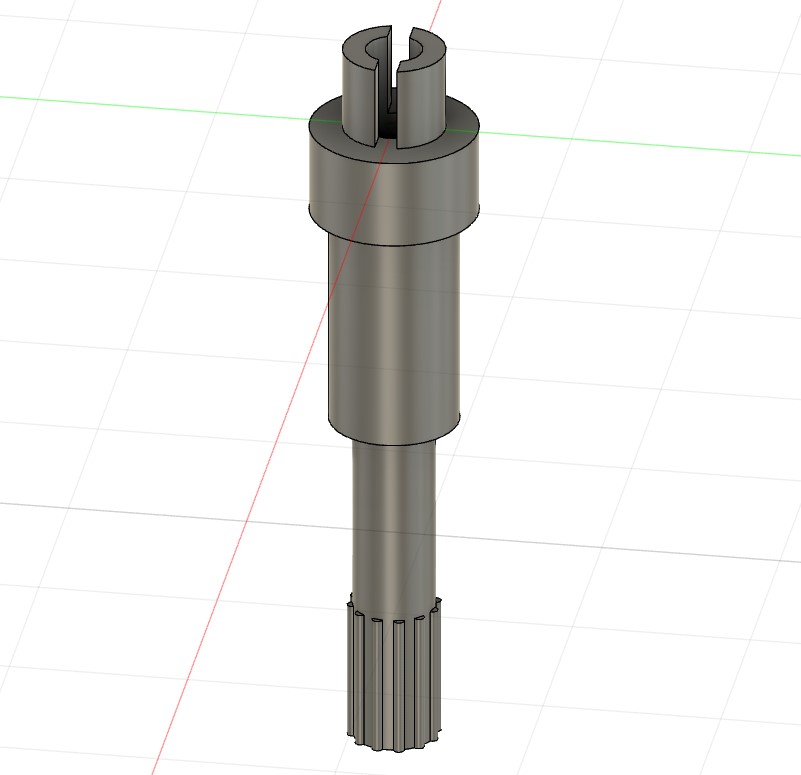

This magnetic lamp fell off my bandsaw and hit the floor shattering the black peg style switch. I took it apart and modeled a new one for the 3D printer. I had my doubts but it was a near perfect copy and the geometry was pretty simple to do for a beginner.

Kind of complicated, it holds a spring that pushes on a brass rod that rests across the metal contacts on and off depending on the 90 degree position it’s rotated. The clicking on and off sound is the spring riding up the ramps and dropping on its position.

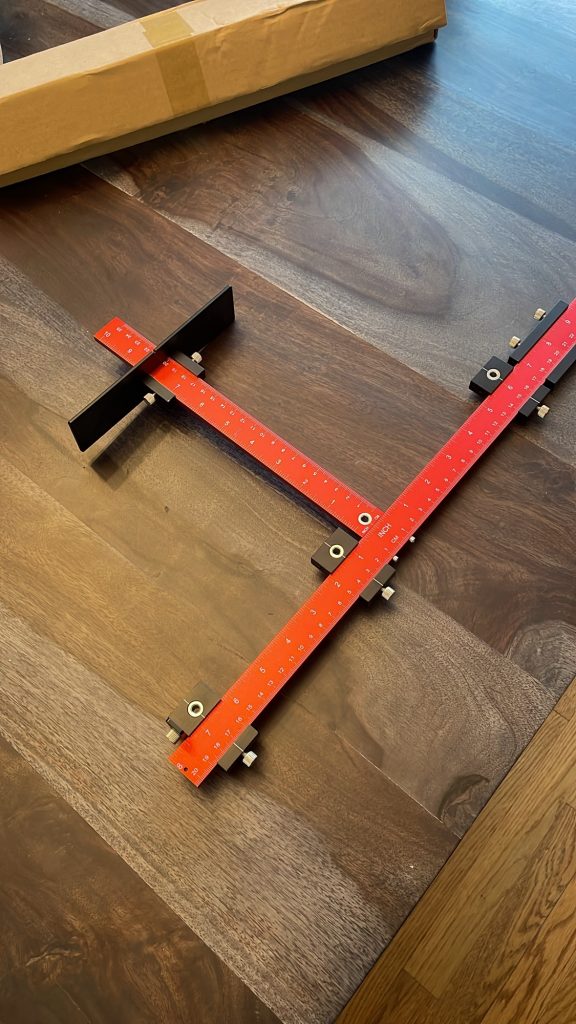

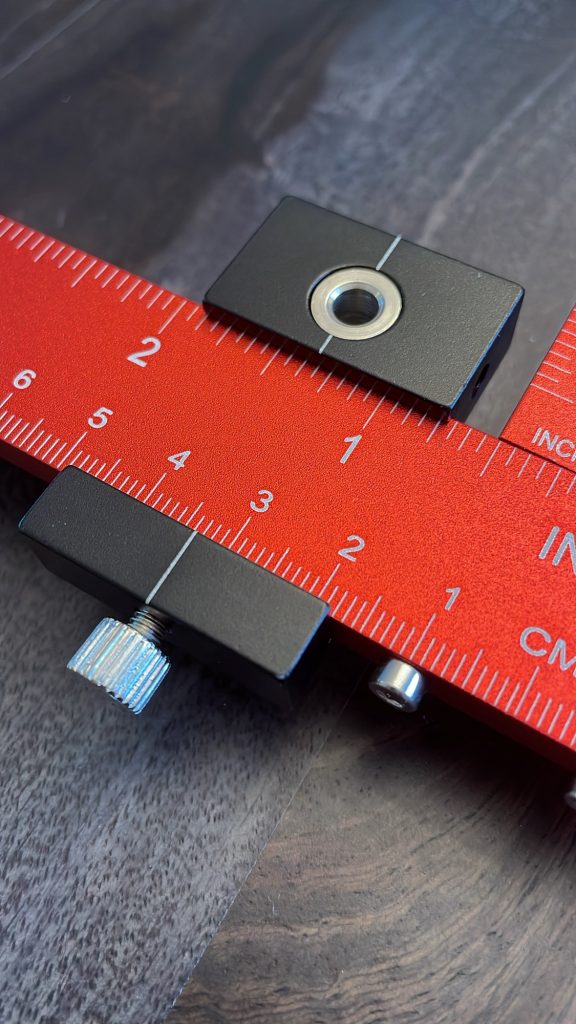

Wow, gotta hand it to made in China tools sometimes. The quality of this cabinet hardware drill position jig is pretty great (knock off of the True Position tool). I thought the joints would be loose and the paint markings sloppy but everything is crispy. I saved over $200 on this one, fine for me, it’s a once in a while tool.