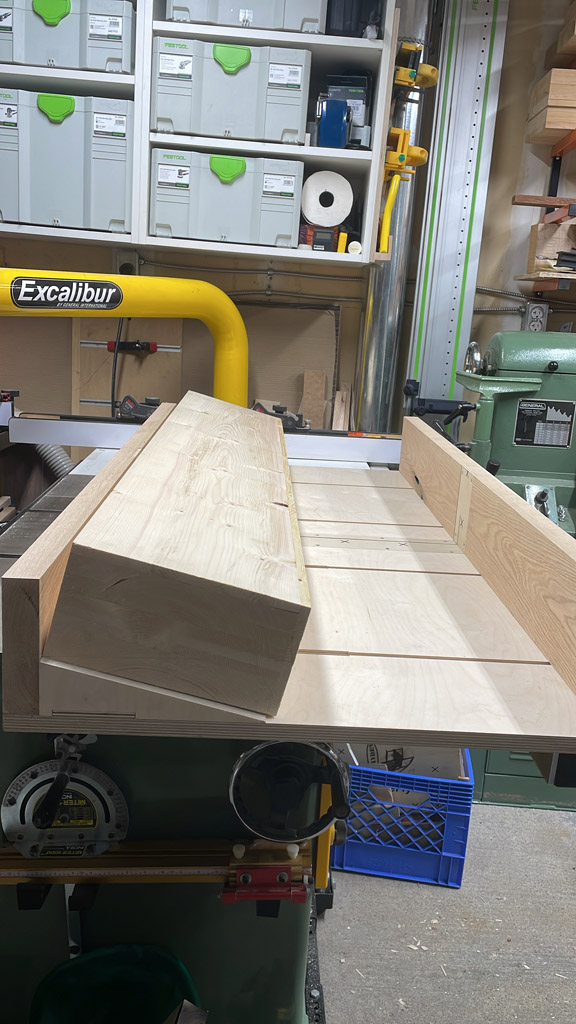

This is my second one.

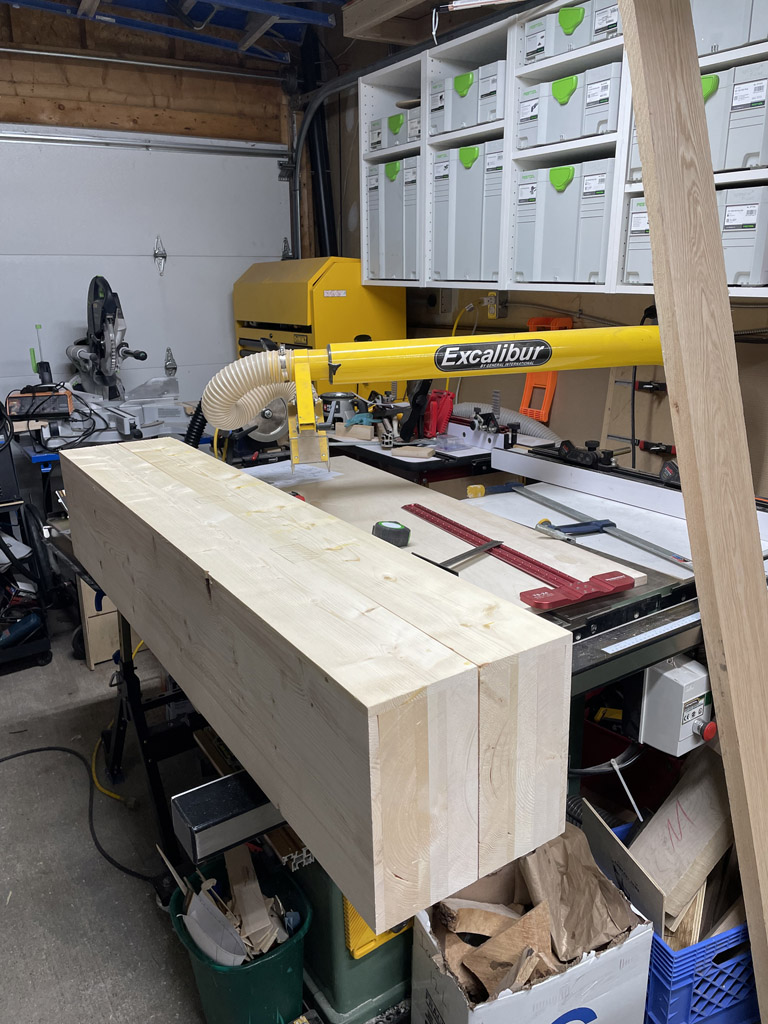

I’ve finished restoring this old book press. When I picked it up at an auction it was rusted and seized up like a brick. When I removed all of the rust a couple pieces were broken. Looked like a challenge!

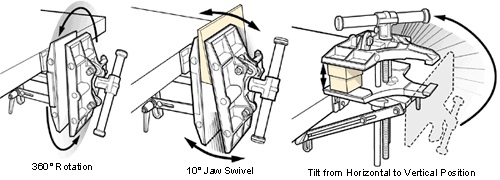

I taught myself to TIG weld and fixed the broken hand wheel and remade the broken flange that bolts onto the upper flat press using a pipe flange welded to a large bolt. Then bought a metal lathe to turn it into the same shape as the original.

Bondo and paint to make it pretty. Most of the threaded things had to be re-threaded and tapped. I learned what ACME thread was and Witworth British thread is.

This book press took many hours and new tools for the learning experience.

For sale for one million dollars.