I made these recently as gifts.

First I glued up strips about 40 inches long of alternating colors of walnut and maple. The 2nd board is opposite colors.

The 1st panel consist of the following strips:

Walnut:

• 3 mm – 1 pc;

• 5 mm – 2 pcs;

• 9 mm – 2 pcs;

• 15 mm – 2 pcs;

• 24 mm – 2 pcs;

• 38 mm – 2 pcs;

Maple:

• 4 mm – 2 pcs;

• 7 mm – 2 pcs;

• 12 mm – 2 pcs;

• 19 mm – 2 pcs;

• 29 mm – 2 pcs;

Total: 21 pcs.

The 2nd panel:

Maple:

• 3 mm – 1 pc;

• 5 mm – 2 pcs;

• 9 mm – 2 pcs;

• 15 mm – 2 pcs;

• 24 mm – 2 pcs;

• 38 mm – 2 pcs;

Walnut:

• 4 mm – 2 pcs;

• 7 mm – 2 pcs;

• 12 mm – 2 pcs;

• 19 mm – 2 pcs;

• 29 mm – 2 pcs;

Total: 21 pcs.

The when dried I ran them through the planer to smooth them out.

Then I cut horizontal strips about 40mm wide of each and flipped them end grain facing up, then mixed them with each other to make opposite color patterns.

Next I took the 40mm strips and cut them the same thicknesses as above and alternate the colors.

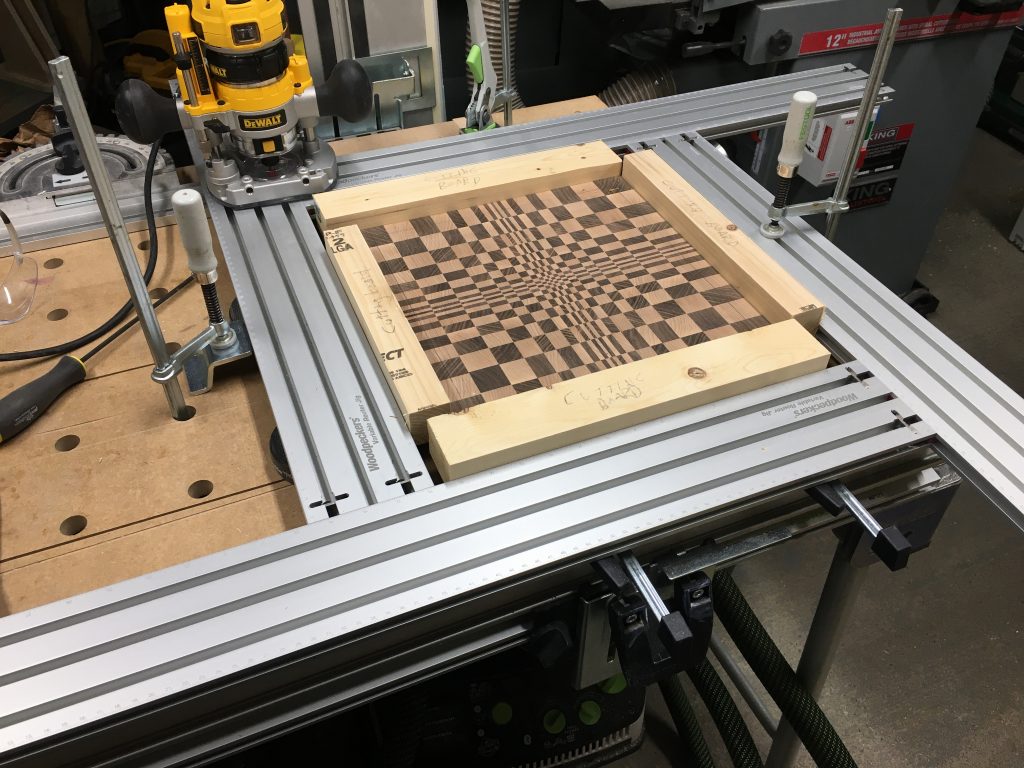

This is how I routed the juice groove, I set up a square jig and put spacers for my router to follow around the inside, the juice groove was about 3/4″ in from the edge.